Visio P&id Symbols

Lucidchart features a huge library with P&ID symbols. Use this legend to better familiarize the most common P&ID symbols and notations including pipes, instruments. Rewards Later. Get great deals on select models now and receive a digital coupon worth up to $100. For a limited time when you purchase select products on.

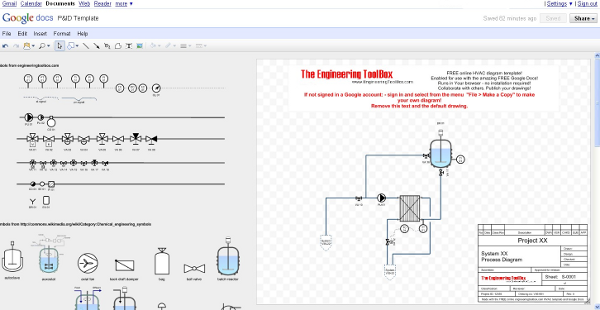

What is P&ID? P&ID is the diagram which shows the interconnection of process equipment and the instrumentation used to control the process. The uses of P&ID are as follows • P&ID is the basis for developing the control systems in the chemical process. • It helps in Equipment design and Piping design and also serves to estimate the capital cost. • is performed during the design stage with the help of P&I diagram.

• It will assist in preparing Commissioning procedure, Pre-Startup Safety Review, Standard Operating Procedures for Startup, Normal operation and Shutdown. • It also assists in preparing • Control narrative and Interlock narratives will be prepared by having P&ID as the basis. • It will help to prepare the Instrument Index and other will serve as a reference for creating other datasheets.

• It acts as a in a Chemical Industry. • P& ID also helps in Incident investigations to find out What Went Wrong through root cause analysis. • It helps in evolving maintenance procedures of equipment. It helps to visualize the interconnecting systems with the equipment and planning for proper isolation can be done. What is the difference between P&ID and PFD? Process Flow Diagram (PFD) is used for indicating the general flow of process and equipment. It helps to visualize the overall process of the in a chemical plant. PFD will contain main process piping, Main equipment number, Equipment Name, Flow directions, Major bypass lines, Critical Control Valves that affects the process, Stream Number, Stream Designation, Process parameters like operating temperature, operating pressure, flow rate, Composition and heat duty of heat transfer equipment.

PFD will not contain Piping size and classification, Process control Instrumentation details like Transmitters, Control valves, Design Temperature and Pressure, Material of Construction of Equipment and piping, Mechanical Valves for isolation, Vents and Drains, Relief valves & Safety Valves. P&ID will contain Equipment number, Equipment Name, Process and Utility piping, Piping size and classification, Instrumentation details like Transmitters, Control valves with their numbers, Control input and output, Annunciation input, SIS input, solenoid valves, On-off valves, Motorised valves, Relief valves, All Mechanical valves Miscellaneous items like strainers, Vents, drains, Silencers, standpipes etc, Vendor items and interfaces, Equipment design pressure, Temperature and Material of Construction, Free draining requirements etc. P&ID will also have general notes that will assist during Detailed Engineering, Erection and Commissioning phase. Though it is not an exhaustive list, Our P&ID Check list in the trailing part of this post will help you to explore in detail about Piping and Instrumentation Diagrams. P&ID will not contain Operating parameters, Equipment elevation details, Elbows, MTO, etc. It is not drawn to scale and hence geometric accuracy can not be expected out of P&ID. Automatic Milk Collection System Software.